Hydraulics is a technical system that uses fluids – usually oil – under pressure to perform mechanical work. This principle is found in numerous industrial, mobile, and stationary applications, ranging from excavators and mechanical engineering to elevator systems. Power transmission via fluid offers high power density, precise controllability, and reliable operation – even under extreme conditions.

Basic Principles of Hydraulics

At the core of hydraulics is the physical property of fluids being incompressible under pressure. When pressure is applied to a fluid, the force is transmitted evenly in all directions – a principle that can be utilized in many technical applications. The resulting movement or force can be precisely controlled and regulated.

Key Components of a Hydraulic System

A typical hydraulic system consists of several key elements that work together to generate motion and force:

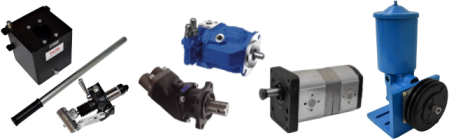

Hydraulic Pump:

The hydraulic pump is the heart of the system. It converts mechanical energy into hydraulic energy by drawing in hydraulic fluid and feeding it under pressure into the system. Depending on the application and power requirements, various pump types are used, including gear pumps, piston pumps, and vane pumps.

Hydraulic Power Unit (HPU):

The hydraulic power unit is a complete assembly that includes the hydraulic pump, electric motor, tank reservoir, filters, and control elements. It provides centralized hydraulic energy to machines or systems. Especially in industrial environments, the power unit plays a crucial role in the efficiency and reliability of operations.

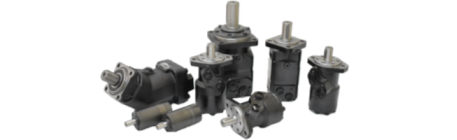

Hydraulic Motor:

The hydraulic motor converts the stored hydraulic energy back into mechanical energy – usually in the form of rotary motion. It acts as the counterpart to the pump and is used in conveyor belts, construction machinery, or agricultural equipment where high torque and compact design are required.

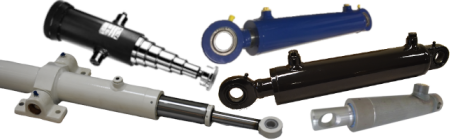

Hydraulic Cylinder:

The hydraulic cylinder is the component responsible for linear motion. Hydraulic pressure moves a piston within the cylinder, which directly performs mechanical work such as lifting, pushing, or pulling. Available in various sizes and configurations, hydraulic cylinders are critical in nearly all hydraulic applications.

Advantages of Hydraulics

Hydraulic systems offer numerous advantages over mechanical or electrical alternatives:

- High power density in a compact space

- Precisely controllable movements

- Overload protection via pressure relief valves

- Long service life with proper maintenance

- Flexible design and adaptable performance

Areas of Application

Hydraulic systems are used in a wide range of industries:

- Construction: in excavators, cranes, and wheel loaders

- Agriculture: in tractors and harvesting machines

- Industrial Equipment: for presses, injection molding machines, and machine tools

- Aerospace: in landing gear and control surfaces

- Automotive Engineering: e.g., in lifting platforms and braking systems

Hydraulics is a core technology across many areas of modern engineering. With the targeted use of components such as hydraulic pumps, power units, motors, and cylinders, it is possible to build powerful, precise, and reliable systems. For companies seeking efficient and robust solutions for power transmission and control, hydraulics remains an indispensable key technology.

Expert Solutions from Taon Hydraulik

At Taon Hydraulik, we offer customized solutions in modern hydraulic technology. Our clients benefit from high-quality components such as hydraulic pumps, powerful power units, durable cylinders, and reliable motors – combined with expert advice and fast delivery.

Feel free to contact us if you are planning a new system or looking to optimize existing equipment. We support you with experience, expertise, and technical solutions.

Phone: +45 24 48 84 80

Email: info@taon.dk