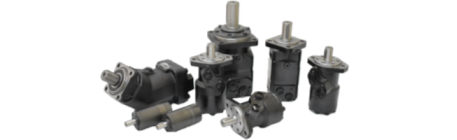

MSS Hydraulic Motors

2.976 DKK

(excl. VAT)3.048 DKK

(excl. VAT)3.126 DKK

(excl. VAT)3.198 DKK

(excl. VAT)3.298 DKK

(excl. VAT)2.900 DKK

(excl. VAT)2.920 DKK

(excl. VAT)MMS Hydraulic motor description

The MSS series from TAON is a powerful and versatile line of orbital motors designed to deliver high performance and operational reliability in demanding hydraulic applications. The motors are based on advanced geroler technology with disc valve flow control, ensuring smooth and efficient startup even at low speeds. Suitable for both mobile and stationary hydraulic systems, the series excels under conditions of high pressure drop and heavy loads. The robust design, including strong tapered roller bearings on the output shaft, makes the motors ideal for applications involving high axial and radial forces.

With automatic internal flow compensation and high-quality components, the MSS series offers long service life and minimal maintenance. The wide range of displacement volumes and torque ratings makes these motors especially suitable for various industrial and mobile applications such as agricultural machinery, construction equipment, and conveyor systems.

Technical Description

The MSS series includes nine different models with displacements ranging from 80.6 cm³/rev to 475 cm³/rev, depending on the application. Maximum speed varies from 800 rpm (MSS 80) down to 155 rpm (MSS 475), offering great flexibility in terms of speed and torque.

The motors are designed to deliver high torque – from 225 Nm up to 910 Nm continuously, and up to 990 Nm in intermittent operation. Working pressure varies by model but allows for pressure drops up to 295 bar. Maximum oil flow typically ranges from 65 to 90 L/min depending on the model.

The output shaft is constructed with heavy-duty bearings to support external loads directly, eliminating the need for external support bearings in many applications. The motor’s rotation direction is determined by pressure: port A causes clockwise rotation (viewed from the shaft end), while port B results in counterclockwise rotation.

The MSS series also features precise mounting dimensions for easy integration into existing hydraulic systems. Weight varies from approximately 9.8 kg to 14.3 kg depending on the model, and the compact design ensures efficient space utilization in tight installations.